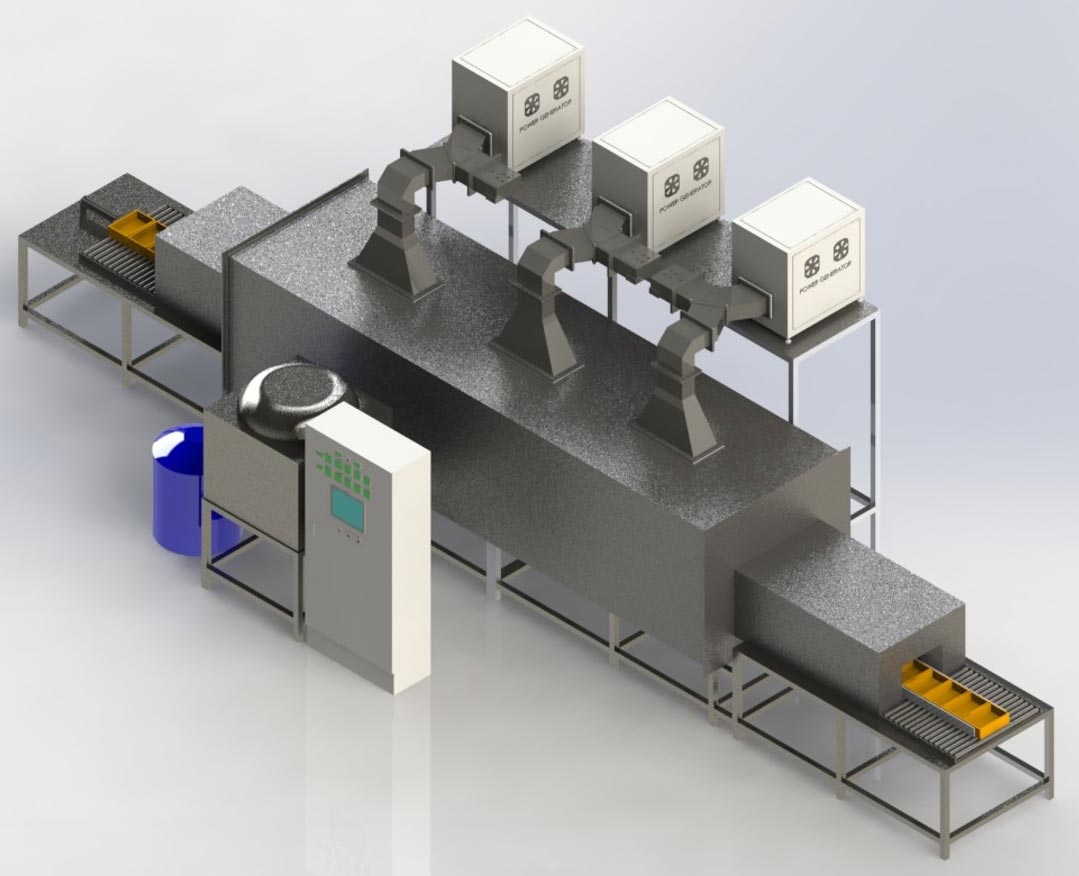

Drying

Continuous Microwave Hybrid Dryer

This model utilizes the conventional principles and the microwave drying uses volumetric heating rather than surface heating.

As shown in the figure, this model discharges moisture from the inside of the materials being dried. This shows a large difference in efficiency from the conventional heat method that dries only the exterior.

Outstanding energy savings

The conventional heat drying method dries the object from the outside and let the heat reach the inside via heat transfer to blow water vapor. However, the microwave drying method transfers heat from the inside. This method allows highly efficient drying effects within only short time range. Therefore, energy saving effect is indeed great. Compared to the conventional heat drying method, the thermal efficiency can be increased up to 30% or more according to the usage conditions.

Reduced equipment size

Thanks to highly efficient drying process, the continuous dryer can reduce the length of the equipment up to 1/3 compared to conventional heat dryer, which allows for efficient space utilization. Comparing the size by the area that it takes, the microwave dryer requires only 42m2 area, while the conventional heat dryer requires an area of 400m2 for equivalent drying results.

Improved product quality

Rapid and uniform drying reduces the likelihood of surface overheating, surface hardening, and cracking due to drying stress. During food processing, the dryer shows excellent effects on the maintenance of color and fragrance. Furthermore, the shortening of the drying process timespan does not give time for bacteria growth, so there is no need for fumigation or other chemical treatments to eliminate bacteria.

Less operation costs

Because the dryer size is reduced and the timespan is reduced, it is easier to stop or restart the system for facility adjustment, product change, cleaning and maintenance. This advantage leads to the reduction of operation costs.

This facility can be applied to drying of insulating materials, drying of agricultural, marine products, drying of paste products (food), drying of particles for chemical industry, etc. Please contact us for further details and the inquiry will be resolved through experiments.