Mixing

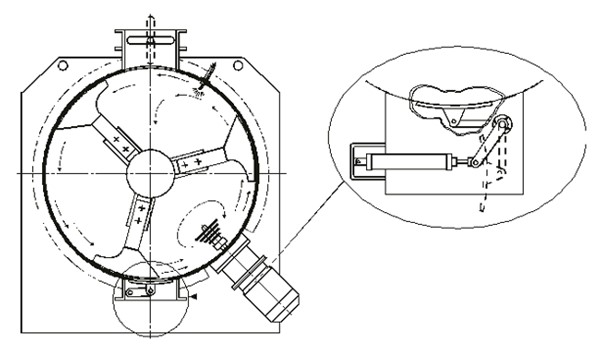

Shovel Mixer

• Consisted of horizontal main body, one shaft and shovel type wing, driving device, high speed chopper, etc.

• The plow-shaped wing forms a fluidized layerdue to the constant rotational speed, and moves the mixture in horizontal direction to mix the raw materials.

• When small amount of additive or liquid are added. high-speed chopper can be used to produce dispersion effect and milling effect.

• After completely mixing the raw materials, the discharge starts from the outlet of the central part and the outer wing pushes the raw materials inward, and it is possible to discharge the mixture when there is no outlet.

• It is very suitable for mixing raw materials with big difference in particle size and proportions. Advantageous for quick mixing.

• When mixing Powder + Powder form,small amount of additive has a very good effect on mixing results.

• When using high speed chopper, there is almost no deposit of raw materials.

• Raw materials are massaged while mixing. Accordingly, those raw materials that require both mixing and reacting are very suitable.

• It is excellent in crushing and mixing with high speed chopper, especially flour, starch, rice flour + shortening.

• Abrasives such as chemical products, food, medicine, pesticide, feed, plastics, brake lining

• Powder + liquid, powder + small amount of additives, and complex processing

• Especially effective for mixing sticky and deadlocked additives.