Quality Assurance-Physical

Thickness Testing

The thickness of a tablet is critical to its therapeutic efficacy since thickness impacts on disintegration and dissolution behaviour. In addition, thickness can be a useful indicator of the consistency, or otherwise, of tablet weight which is controlled to ensure dose uniformity.

The weight of a compressed tablet is dependent on three factors: Density, Diameter, Thickness.

Though a modern tablet press should provide a good level of uniformity, there are several potential sources of variation, the most important of which is powder flow which can affect the uniformity with which the die is filled before compaction. Mechanical wear and imperfections in the pressing or tooling may also introduce variability, as can the build-up of material on the punch face or die wall during a run. Any of these factors may impact tablet weight and the physical consistency of manufactured tablets.

Monitoring tablet thickness at regular intervals allows potential problems relating to tablet weight and hence content uniformity to be detected and efficiently diagnosed at an early stage.

Easy-to-operate and portable tablet thickness testers for busy production environments

Copley’s range of calipers and thickness testers are simple and easy-to-use instruments, designed for use by the press operator on the compression floor.

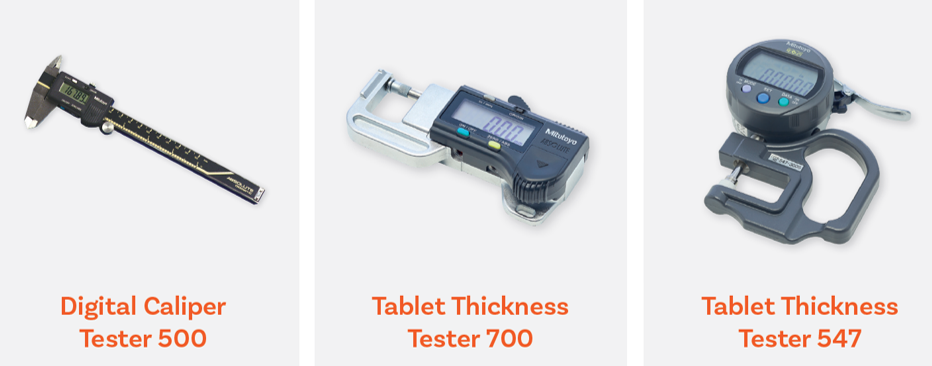

- Digital Caliper Model 500

Accepting tablets and similar samples up to a maximum size of 150mm, the inexpensive Digital Caliper 500 is a convenient, hand-held electronic caliper, for quick, simple and convenient tablet thickness testing.

Supplied in a handy plastic storage case, the Digital Caliper 500 can be readily connected to data processor units for statistical process control.

- Tablet Thickness Tester 700

A dedicated pocket-sized unit for simple, one-handed operation. Just switch the device on, zero the gauge, select the units, insert the sample, release the jaw and read off the measurement on the clear LCD display.

- Tablet Thickness Tester 547

A more sophisticated unit than the Tablet Thickness Tester 700, this gauge enjoys many of the same features but can be used in two different modes:

a) ‘Direct measurement’ mode which provides actual thickness

b) ‘Comparator measurement’ mode whereby a +/- variance from a pre-set norm is indicated on the display. This is extremely useful for rapid checks in the production environment.