Screen Surface

Woven Wire Screens

High quality screen surfaces are vital to the performance of Derrick high speed screening machines. Derrick fabricates compatible screen panels for use on all models in its equipment line. A number of Derrick screen tensioning assemblies are also available. These greatly enhance the performance of our fine mesh screens.

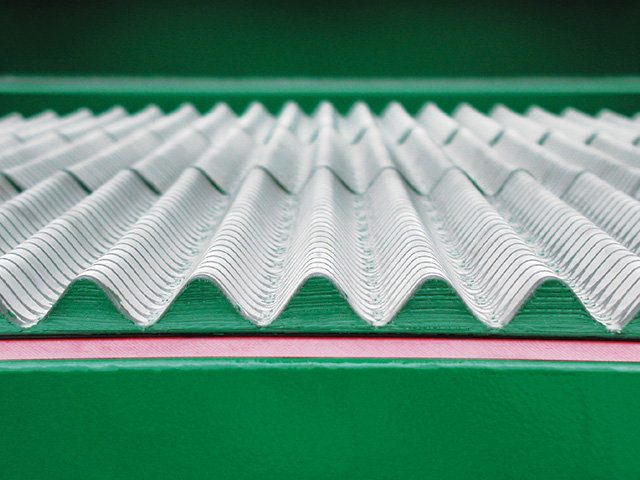

Pyramid (PMD) and Pyramid Plus (PMD+) Screen Panels

Derrick Equipment Company revolutionized screening technology in 1994 with the introduction of the patented Pyramid (PMD) screen design. This three-dimensional screen design offers the benefits of traditional flat, multi-layered screens while adding a substantial increase in usable screen area. The result is a screen that allows for an increase in fluid handling capacity. Pyramid technology allow rigs to screen finer earlier in the drilling process, thus significantly reducing total drilling fluid and disposal costs.

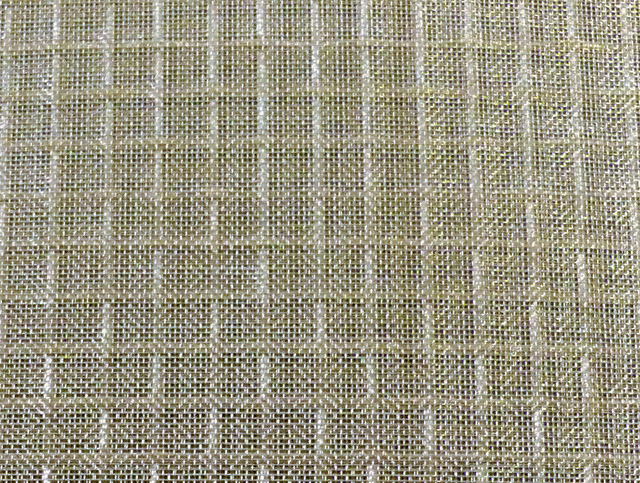

Sandwich (SWG) Screen Panel

The anti-blinding Derrick Sandwich screen consists of two fine mesh screens supported by a coarser backing wire screen. Interference in the free openings is created by cross wires of the second screen. This layered effect prevents particles from lodging in the openings of the top sizing surface and provides longer screen panel life. The cut point is made by the combination of cross wires from both fine screen surfaces.

Standard Wire Screens

Derrick supplies square or slotted wire screen cloth in standard meshes and wire diameters. These are designed with double fold, hook strip, box bindings for secure and easy installation.

Floating Backing Wire

The Floating Backing Wire screen allows fine separations in applications traditionally not considered feasible for fine screening technology. Some screen feeds contain moisture, hydroscopic material or static charge which can cause fine particles to cling to the screen surfaces. Eventually this clinging material "bridges" over the screen surface and stops the screening process. The Floating Backing Wire screen eliminates this bridging process and allows for continuous operation with no loss of screen surface area. A perfect solution to difficult fine screening operations.

- Pyramid™ (PMD™) and Pyramid Plus™ (PMD+™) Screen Panel

- Sandwich (SWG™) Screen Panel

- Standard Wire Screens

- Floating Backing Wire